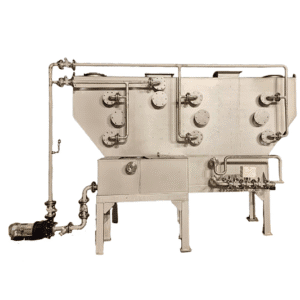

Stainless Steel Mixing Tank Product Introduction The stainless steel mixing tank is an industrial equipment integrating functions such as stirring, mixing, and reaction. With its excellent performance and wide applicability, it occupies an important position in many industries including chemical industry, food, pharmaceutical, and environmental protection. This mixing tank is meticulously crafted from high-quality stainless steel materials (such as 304, 316, etc.). This material not only endows the tank body with excellent corrosion resistance, which can effectively resist the erosion of various media such as acids, alkalis, and organic solvents, and prolong the service life of the equipment, but also ensures the purity of the materials in the tank. It is especially suitable for fields with high hygiene requirements such as food and pharmaceutical industries. In terms of structural design, the stainless steel mixing tank emphasizes practicality and rationality. The tank body is mostly a vertical cylinder, and the tank bottom can be designed into flat bottom, cone bottom, or elliptical bottom according to requirements, which facilitates the discharge and cleaning of materials. The top of the tank is equipped with a stirring device, which consists of a motor, a reducer, a stirring shaft, and stirring blades. Different types of blades (such as paddle type, anchor type, turbine type, propeller type, etc.) can be selected according to the properties of the materials (such as viscosity, density, mixing requirements, etc.), ensuring that the materials can be fully and evenly stirred. At the same time, the tank can also be equipped with accessories such as feed ports, discharge ports, observation windows, manholes, liquid level gauges, thermometers, and pressure gauges according to actual needs to meet the operating requirements of different production processes. The stirring speed of the stainless steel mixing tank can be adjusted through a frequency conversion speed control device, which can adapt to the stirring process requirements of different materials, from low-speed stirring to high-speed dispersion. In terms of heating and cooling, the tank body can be designed into a jacketed or coiled structure. Heating can be carried out by introducing heat sources such as steam, hot water, and heat-conducting oil, or cooling by introducing cold water, chilled water, etc., to precisely control the temperature of the materials in the tank and ensure the smooth progress of the reaction or mixing process. In addition, the equipment also has good sealing performance, using mechanical seals or packing seals, which can effectively prevent material leakage and the intrusion of external impurities, ensuring the safety and cleanliness of the production environment. Moreover, its specifications and sizes can be customized according to the user’s actual production capacity requirements, ranging from a few liters to dozens of cubic meters, fully meeting the needs of production at different scales. Whether it is used for material dissolution, mixing, emulsification, or chemical reaction, fermentation and other processes, the stainless steel mixing tank can provide a strong guarantee for the production process with its efficient, stable, and reliable performance, and is an indispensable important equipment in modern industrial production.

Storage Tanks

Stainless steel mixing tank

1)Create the ideal solution for your needs

2) OEM quality standard guaranteed

3) Competitive prices.

4) Flexible and convenient logistic service.

5) Short-delivery time.

6) Good technical support and after-sales service