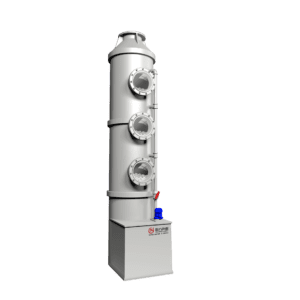

YuanFang PP/PPH Activated Carbon Dry Scrubber: Zero-Liquid Discharge Solution for Hazardous VOCs Control

Engineered to Outperform EU Industrial Emissions Directive (IED) Standards

🔥 Core Technology Advantages

- Triple-Action Purification

- Dry Adsorption Layer: Activated carbon beds capture >99% benzene/toluene/xylene (BTX) at concentrations up to 5000 ppm

- PPH Chemical Resistance: Handles pH 1-14 extremes, eliminating corrosion failures in acid mist/alkali fume scenarios

- Zero-Water Design: 100% dry operation vs. wet scrubbers – slashes wastewater treatment costs by 60%

- Explosion-Safe Architecture

- ATEX-Certified Modules: Static-dissipative PPH construction prevents spark ignition (Zone 1/2 compatibility)

- Pressure Relief System: Auto-venting at 0.5 bar for peroxide-forming solvents (e.g., ethyl ether)

📊 Operational Excellence

| Parameter | Performance | Industry Benchmark |

|---|---|---|

| VOCs Removal | 99.2% @ 2000 mg/Nm³ inlet load | 85-90% |

| Pressure Drop | <800 Pa | 1200-1500 Pa |

| Carbon Life | 12-18 months (regenerable option) | 6-8 months |

| Noise Level | 68 dB(A) with integrated silencer | 75-85 dB(A) |

▶️ Proven in High-Risk Sectors:

- Pharma Synthesis Labs: Meets FDA 21 CFR Part 211 for solvent recovery

- Lithium Battery Recycling: Captures HF/NMP vapors at 98.7% efficiency

- Pesticide Formulation: Neutralizes malathion/chlorpyrifos odors to <5 OU (odor units)

🌿 ESG-Driven Value Proposition

- Carbon Footprint Reduction: 1.2 tons CO₂e saved annually per unit (vs. thermal oxidizers)

- Plastic Circularity: 100% recyclable PPH material (ISO 14067 certified)

- Smart Monitoring: IoT sensors predict carbon saturation ±3% accuracy – prevent breakthrough

Why Global Leaders Trust YuanFang?

- Factory-Direct Precision: ISO 9001-certified vertical manufacturing from resin molding to AI testing

- Rapid Deployment: Pre-assembled skid units – operational in <72 hours

- Lifecycle ROI: 30% lower TCO over 10 years with patented carbon reactivation service