1. Core Product Features

① Superior Material & Anti-Aging Design

- Advanced Materials: Tanks are manufactured using high-density polyethylene (HDPE), polypropylene (PP), and fiber-reinforced plastic (FRP) via rotational molding, ensuring seamless construction with no welds or leaks. These materials provide exceptional resistance to strong acids, alkalis, and organic solvents, ideal for chemical, pharmaceutical, and food processing industries .

- UV & Weather Resistance: Incorporated with UV stabilizers and anti-aging additives, the tanks maintain structural integrity in harsh outdoor environments, with a lifespan exceeding 10 years .

② Flexible Customization

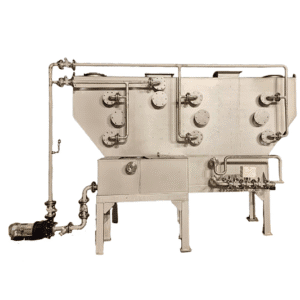

- Tailored Dimensions: Supports non-standard designs, including capacity (500L–20,000L), port configurations (inlet/outlet, sight glasses, manholes), and mounting structures (vertical/horizontal) to adapt to diverse workshop layouts .

- Modular Components: Optional accessories include heating/cooling jackets, temperature sensors, CIP cleaning systems, and multi-layer agitators (anchor, paddle, or turbine styles) .

2. Technical Advantages

- Efficient Mixing Performance: Equipped with variable-speed motors (0.5–15 kW) and precision gearboxes, achieving homogeneous blending for high-viscosity or solid-liquid mixtures .

- Energy-Saving Design: Optimized impeller geometry reduces power consumption by 15–20% compared to conventional models .

- Intelligent Control: Optional PLC automation for real-time monitoring of parameters like temperature, pH, and torque, enabling remote operation and fault alerts .

3. Key Applications

- Chemical Industry: Mixing reactive agents, solvents, or corrosive liquids in pesticide, dye, and resin production .

- Pharmaceutical Sector: Homogenizing APIs (Active Pharmaceutical Ingredients), suspensions, and emulsions under GMP-compliant conditions .

- Food & Beverage Processing: Blending sauces, dairy products, and additives with hygienic, easy-to-clean surfaces .

4. Enterprise Assurance

- Production Capacity: Established in 2005, the company operates a 30-acre modern facility with automated production lines, capable of delivering 1,000+ units annually .

- Quality Certification: ISO9001-certified manufacturing processes ensure reliability, with products exported to Europe, the Middle East, and beyond .

- End-to-End Service: Provides customized engineering design, installation guidance, and 24/7 after-sales support to minimize downtime .