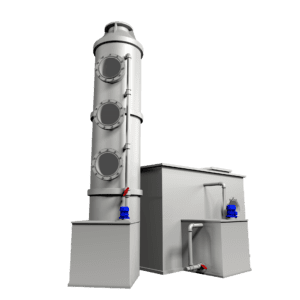

Henan YuanFang Environmental Protection Equipment Co., Ltd. (ISO 9001 certified , these towers excel in absorbing harmful gases (e.g., acidic fumes, VOCs) and recovering valuable chemicals, achieving purification rates exceeding 98%. Ideal for chemical, pharmaceutical, metallurgical, and electronic industries, the tower’s modular design ensures compliance with China’s Ultra-Low Emission standards and global environmental regulations .

Key Advantages

-

Superior Corrosion Resistance & Durability

-

Constructed with seamless PP or composite materials , resistant to acids, alkalis, and organic solvents, ensuring longevity in harsh conditions.

-

Rotational molding technology eliminates welding seams, preventing leaks and extending service life by 2–3× compared to traditional towers .

-

-

High-Efficiency Mass Transfer

-

Vertical columnar structure with optimized gas-liquid distribution enhances contact surface area, achieving rapid absorption and >98% purification efficiency .

-

Integrated cooling jacket system stabilizes temperatures during exothermic reactions, maintaining consistent performance .

-

-

Energy-Saving & Low Maintenance

-

Low-resistance design reduces energy consumption by 20–30% compared to packed towers, minimizing operational costs .

-

Smooth internal surfaces resist scaling and blockages, reducing downtime and cleaning frequency .

-

-

Versatile Configuration

-

Customizable capacities (1–100 m³/h) and modular components (e.g., multi-stage absorption layers, demisters) adapt to diverse gas compositions and flow rates .

-

Compatible with hybrid systems (e.g., combined with spray towers or activated carbon filters) for complex emission scenarios .

-

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | PP, FRP, or customized composites |

| Capacity Range | 1–100 m³/h |

| Temperature Range | -20°C to 120°C (PP) / up to 150°C (FRP) |

| Pressure Resistance | ≤0.3 MPa |

| Purification Rate | ≥98% |

| Optional Features | Cooling jackets, demisters, multi-stage absorption layers |

Industry Applications

-

Chemical & Petrochemical: Absorption of HCl, SO₂, NH₃, and solvent recovery .

-

Pharmaceutical: Removal of acidic gases and VOC emissions from synthesis processes .

-

Electronics & Metallurgy: Treatment of etching fumes and metal surface treatment exhaust .

-

Environmental Remediation: Neutralization of industrial waste gases to meet emission standards .