Bubble column scrubber is used to neutralize the acidic, alkali fumes coming from laboratory. In some instances, the harmful fumes emitted from the chemicals cannot be directly released to the atmosphere.In order to reduce the harmful fumes before they evacuate the system and to control air pollution, Bubble column fume scrubbers are installed.Bubble column scrubber remove or neutralize the harmful substances emitted from combustion or the storage of chemicals.It works by contacting the target compounds with a scrubbing solution. Often, the solution is simply water, but can be a reagent to address specific chemicals.

1.FEATURES

1.Can handle air flow rate from 100 to 30,000 CFM

2.Removal method is Absorption / Chemisorption

3.Material of Construction: PP, FRP, PP+FRP, MS+FRP, SS 304, SS 316

4.High efficiency Tellerette® Tower Packing removes soluble/reactive gases, solid particulate and liquid droplets down to 7 microns

5.Lower shell serves as integral sump for recycle of liquid

6.Spray nozzles accessible from top of unit

7.Entrainment separators prevent liquid carryover

8.Special multi-bed packing designs accommodate different scrubbing solutions for removal of multiple contaminants

9.Efficiency up to 99%

2.configurations:

We prioritize understanding your facility’s specific requirements to deliver the optimal solution. Our team offers the following configurations for your wet scrubber:

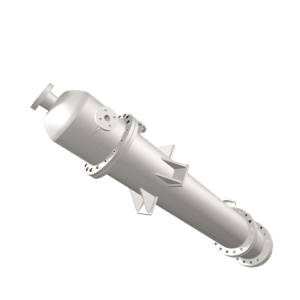

Horizontal Scrubbers: Ideal for applications with limited vertical space or rooftop setups requiring a low profile. In this design, gas flows horizontally while scrubbing liquid flows downward. Multiple stages with individual pumps can be integrated into a single housing if needed.

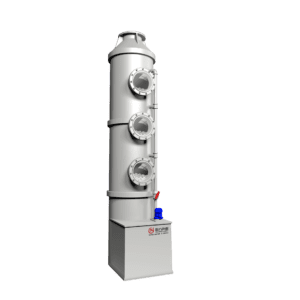

Vertical Scrubbers: A more space-efficient and effective option, where gas moves upward and scrubbing liquid is sprayed downward onto the media. The sprayed liquid effectively absorbs contaminants from the gas.

Multistage Air Scrubbing Systems: Designed for maximum contaminant capture and removal, these systems incorporate multiple stages with diverse scrubbing solutions to thoroughly clean the gas. They are particularly suitable for handling gas mixtures with multiple substances.

3.Tower Materials

Our systems are designed for durability and exceptional performance. To ensure quality, we collaborate with accredited industry-leading suppliers who leverage their expertise and premium materials to engineer and manufacture our packed tower scrubber systems. Built with precision and a focus on safety, Yuanfang solutions utilize the following materials:

Titanium

Mild steel and stainless steel

Fiberglass reinforced plastic (FRP)

Polyethylene

Polypropylene

CPVC and PVC

4、Commom Pollutants Removed

HCl fume Scrubbing

H2SO4 fume scrubbing

Caustic fume scrubbing

Laboratory chemical fumes scrubbing

HF fume scrubbing

Inorganic chemical scrubbing

Plating industries scrubbing

5、Applications

Wet scrubbers are suitable for any industry that produces contaminated airflow. Use a Yuanfang scrubber system for:

1.Chemical industry: Removing acidic waste gases, volatile organic compounds, etc.

2.Pharmaceutical industry: Treating waste gases generated during drug synthesis.

3.Metallurgical industry: Removing soot and sulfur dioxide from metal smelting processes.

4.Food processing industry: Controlling odor gases produced during fermentation processes.

5.Textile and dyeing industry: Eliminating waste gas pollution from dyeing processes.

6.Semiconductor industry: For acidic waste gases, sodium hydroxide or water at 5%-10% concentration is generally used as the absorbent; for alkaline waste gases, sulfuric acid or water is typically used as the absorbent.

Furthermore, wet scrubbers play an important role in treating flue gas generated from waste incineration, especially in neutralizing acidic gases such as HCl, SOx, and HF.