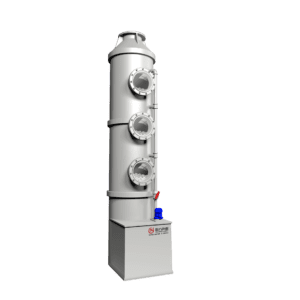

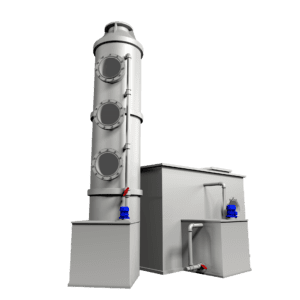

Yuanyang Environmental Acid Fume Scrubber System for Chemical Plants

Designed for chemical plants, electroplating facilities, and pharmaceutical industries, this system employs advanced gas-liquid mass transfer technology to deeply purify acidic exhaust gases (e.g., HCl, H₂SO₄, NOₓ), complying with China’s Integrated Emission Standard of Air Pollutants (GB16297-2020).

1. Core Technologies

- Multi-stage Purification

- Packed Bed Layer: PP Pall rings or Raschig rings increase gas-liquid contact area by 40%, ensuring full reaction between acid mist and absorbent (e.g., 5% NaOH)

- Spray System: Corrosion-resistant spiral nozzles achieve ≥95% mist coverage, suitable for high-concentration fumes (e.g., sulfuric acid mist input 4000 mg/m³, output <45 mg/m³).

- Demister Module: Dual baffle+mesh design with 99% droplet removal efficiency.

- Smart Control

- Real-time pH/ORP monitoring auto-adjusts chemical dosing, reducing reagent consumption by 15%.

2. Key Advantages

- Durability: Enhanced PP or FRP structure withstands -20℃~120℃, anti-corrosion, service life ≥10 years.

- Energy Efficiency: System resistance ≤800 Pa, 30% lower energy consumption vs. conventional scrubbers.

- Customization: Modular design for 1000-100,000 m³/h airflow, expandable with activated carbon or plasma units

3. Applications

- Chemical Industry: HCl/HNO₃ mist treatment (≥98% efficiency);

- Electroplating/Metallurgy: Chromic acid/HF exhaust control;

- Waste Treatment: H₂S/NH₃ odor removal