Analysis of Design Parameters for a 10,000 CFM wet Scrubber

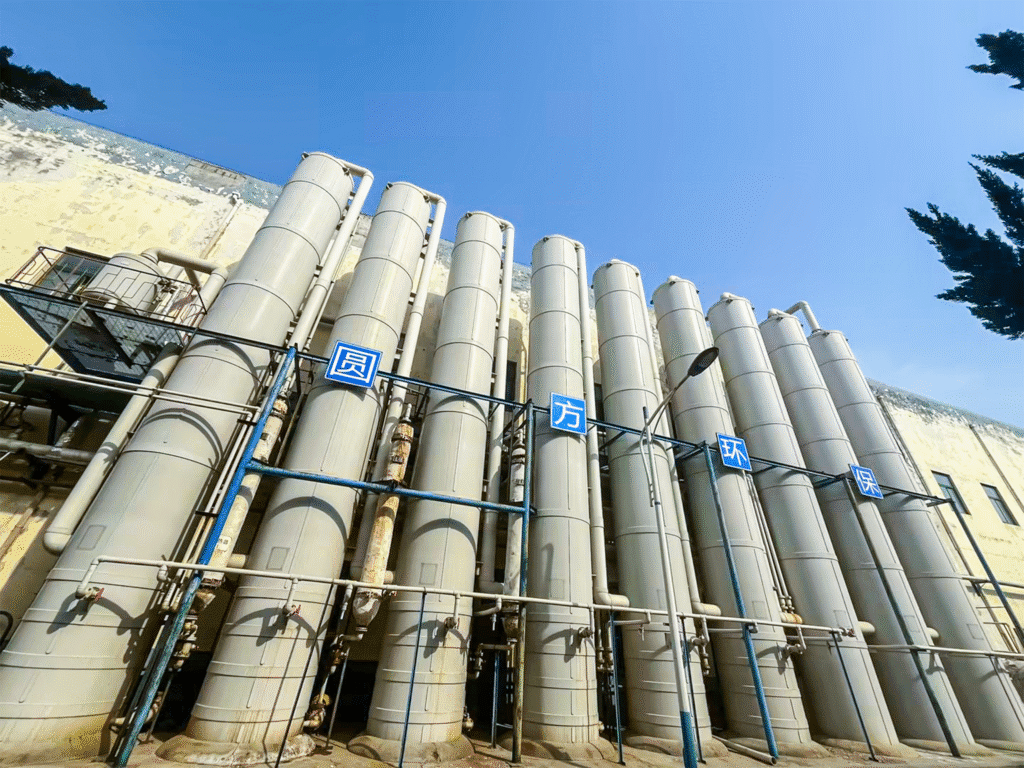

In the field of industrial waste gas treatment, scrubbers serve as core equipment, and their dimensional design directly impacts purification efficiency and operational costs. Taking a scrubber designed for a 10,000 m³/h air volume as an example, its diameter, height, and internal structure need to be optimally configured through scientific calculations and engineering validations. This article systematically explains the design logic of such scrubbers by combining industry standards with practical cases.

1. Diameter Design: The Golden Balance of Superficial Gas Velocity

The determination of the scrubber’s diameter follows the principle of superficial gas velocity, which refers to the average flow rate of the waste gas across the tower’s cross-section. Based on engineering experience, the superficial gas velocity should be controlled within the range of 1.5-2.5 m/s:

-

Theoretical Calculation: For an air volume of 10,000 m³/h and a superficial gas velocity of 2 m/s, the diameter can be calculated using the following formula:

In practical engineering, a diameter of φ1500 mm is typically chosen.

- Impact of Gas Velocity: If the diameter is too small (e.g., φ1200 mm), the gas velocity will increase to 2.4 m/s, reducing the contact time between the waste gas and the scrubbing liquid to less than 2 seconds. This results in a more than 30% decrease in the efficiency of acid-base neutralization. Conversely, if the diameter is too large (e.g., φ1800 mm), although the gas velocity drops to 1.1 m/s, the equipment’s footprint increases by 40%, significantly raising investment costs.

Typical Case: An electroplating plant utilized a φ1500×3500 mm scrubber to treat waste gas containing chromium acid mist. With a superficial gas velocity of 1.8 m/s and a packing layer height of 1.5 meters, the measured chromium removal rate reached 92%, validating the reasonableness of the dimensional design.

2. Height Design: The Trade-off Between Residence Time and Purification Efficiency

The height of the scrubber must ensure an adequate residence time for the waste gas inside the tower. Research indicates that:

- For every additional second of residence time, the removal rate of particulate matter increases by 15%-20%, and the absorption rate of acidic gases increases by 10%-15%.

- Segmented Design (example for a total height of 4.6 meters):

Section Height (m) Functional Description Spray Section 1.2 3-4 layers of spray nozzles, liquid-to-gas ratio of 2-3 L/m³ Packing Section 1.5 Two layers of 500 mm Raschig rings, porosity ≥90% Demisting Section 0.8 Combined structure of baffles and wire mesh Buffer and Support Section 1.1 Inlet/outlet flow guides and structural support

Non-linear Relationship Between Air Volume and Height: When the air volume increases from 5,000 m³/h to 40,000 m³/h, the total tower height only increases from 3.6 meters to 6.0 meters, a 66.7% increase that is significantly lower than the eightfold increase in air volume. This is because larger-diameter towers expand the cross-sectional area, enhancing gas-liquid contact and partially offsetting the reduction in residence time caused by increased air volume.

3. Key Parameter Matching: Synergistic Optimization of Power and Materials

- Pump Power:

- When treating waste gas containing dust, the liquid-to-gas ratio should be ≥3 L/m³. For an air volume of 10,000 m³/h, the corresponding pump power is approximately 3.75-5.5 kW (depending on nozzle pressure requirements).

- For acidic waste gas treatment, the liquid-to-gas ratio can be reduced to 2 L/m³, allowing the use of a 3 kW pump for the same air volume.

- Inlet/Outlet Pipe Diameter:

-

Based on a gas velocity of 15-20 m/s, the pipe diameter for an air volume of 10,000 m³/h can be calculated as:

-

| In practical engineering, a **DN400 mm** pipe diameter is typically chosen, along with 45° flow guides to prevent gas flow deflection. |

3. Material Selection:

- PP (Polypropylene): Resistant to acid and alkali corrosion, low cost, suitable for acidic waste gas at room temperature (e.g., HCl, H2SO4).

- FRP (Fiberglass Reinforced Plastic): Resistant to high temperatures (≤80°C) and has high strength, suitable for high-concentration waste gas in the chemical industry.

- Stainless Steel 316L: Resistant to chloride corrosion, suitable for waste gas containing fluorine or high-temperature environments.

4. Engineering Practices: Three Principles for Parameter Selection

- Process Priority Principle:

- When treating high-concentration VOC waste gas, the superficial gas velocity should be reduced to 1.2 m/s. In this case, even for an air volume of only 10,000 m³/h, the diameter needs to be expanded to φ1800 mm to accommodate the installation of an activated carbon adsorption layer.

- Cost-Effectiveness Balance:

- When the air volume exceeds 100,000 m³/h, a multi-tower parallel configuration (e.g., two φ3000 mm towers) is more cost-effective than a single large tower, reducing equipment investment by 20%-30%.

- Future Scalability:

- Design should include a 10%-20% air volume margin. For example, a tower designed for 15,000 m³/h can accommodate a future increase to 20,000 m³/h by increasing the packing layer thickness from 1 meter to 1.5 meters.

5. Common Misconceptions and Solutions

- Misconception: Blindly increasing the diameter to handle higher air volumes.

- Consequence: Excessively low gas velocity leads to insufficient gas-liquid contact, causing the packing layer to clog easily.

- Optimization: Use CFD (Computational Fluid Dynamics) simulations to optimize spray density and packing distribution.

- Misconception: Neglecting the demisting section design.

- Consequence: Mist droplets carrying chemicals can corrode downstream equipment (e.g., fans, chimneys).

- Optimization: Employ a two-stage demisting system (baffles + wire mesh) to ensure a mist capture efficiency of ≥99%.

Conclusion

The design of a scrubber for a 10,000 m³/h air volume must balance gas velocity control, residence time, and power matching. A standard size of φ1500×4600 mm, combined with PP material and a modular packing layer, can achieve an acidic gas removal rate of over 90%. In practical engineering, it is advisable to fine-tune parameters based on waste gas composition, temperature, and site conditions, and to validate them through pilot-scale tests to achieve a balance between economic and environmental objectives.